Introduction to Electroactive Polymers (EAPs)

Electroactive polymers (EAPs) represent a class of smart materials that exhibit a remarkable ability to change shape or size when subjected to an electric field. These polymers can be thought of as artificial muscles, as they are capable of mimicking the contractile properties of biological tissues. The significance of EAPs lies in their unique characteristics, which enable them to convert electrical energy into mechanical movement efficiently. This transformation is achieved through various mechanisms, including ionic conduction, dielectric effects, and electromechanical coupling.

One of the defining features of electroactive polymers is their versatility. These materials can be formulated into different shapes and sizes, catering to a wide range of applications from robotics to medical devices. Their lightweight nature combined with a high degree of adaptability allows for innovative designs that traditional actuators cannot achieve. Additionally, EAPs are capable of operating at low voltages, making them suitable for integration into portable and wearable technologies.

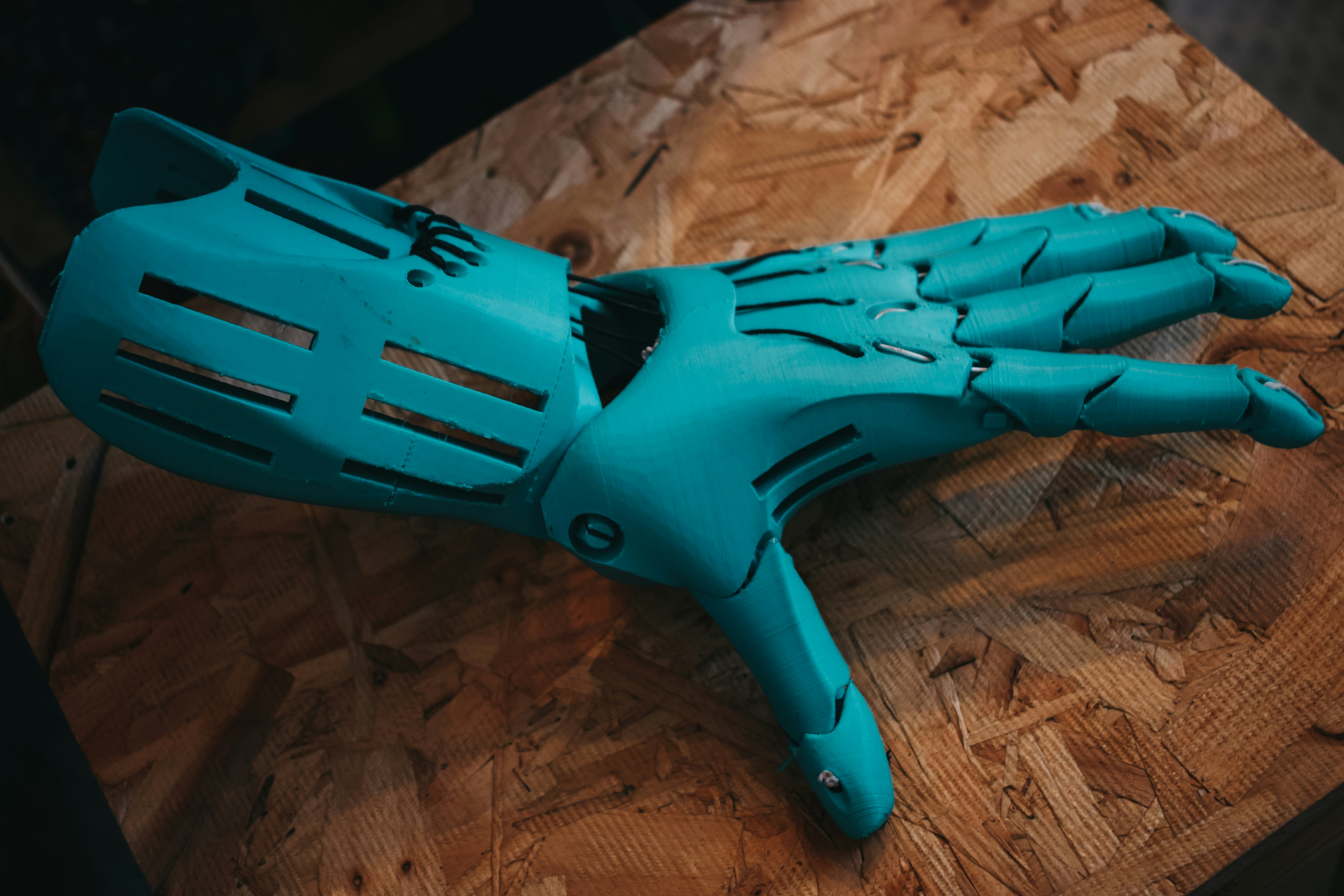

The term “artificial muscles” is often used to describe EAPs due to their ability to produce significant mechanical strain. This capability makes them particularly appealing for applications that require delicate or precise movements, such as in robotic hands or prosthetic limbs. The use of electroactive polymers in these contexts highlights the intersection of materials science and engineering, showcasing their potential to revolutionize how machines interact with the physical world.

As we continue to explore and understand the properties of electroactive polymers, their role in emerging technologies becomes increasingly prominent. By leveraging their unique capabilities, researchers and developers are pioneering advancements in soft robotics, artificial intelligence, and interfacing systems where traditional mechanical components are often inadequate. The future of EAPs looks promising, as they hold the potential to redefine the limitations imposed by conventional materials in the engineering landscape.

The Science Behind Electroactive Polymers

Electroactive polymers (EAPs) represent a fascinating class of materials that exhibit a unique response to electrical stimuli, thereby enabling movement and deformation akin to biological muscles. At their core, EAPs operate on principles that differ significantly from traditional actuation methods commonly utilized in robotic systems. The primary mechanism of action involves the interaction between the polymer’s molecular structure and the external electric field applied to it.

When an EAP is subjected to an electric field, the charged particles within the polymer move, resulting in a reorganization of the material’s molecular chains. This realignment enables the EAP to expand, contract, or bend in a controlled manner, effectively simulating muscle contractions. The alteration in shape or size is predominantly due to electrostatic forces that act on the polymer chains, demonstrating a direct correlation between the applied voltage and the resulting mechanical response.

It is essential to distinguish between the changes at the molecular level and the operational principles of conventional motors. Traditional motors depend on mechanical components and moving parts to generate motion, whereas EAPs rely on the inherent properties of the polymer itself, eliminating the need for complex assemblies that wear over time. This simplicity not only enhances durability but also significantly reduces the weight of the devices, making EAPs particularly attractive for applications in soft robotics and wearable technologies.

Furthermore, the versatility of EAPs can be attributed to their composition, which includes various types of polymers such as ionic, dielectric, and conducting materials. Each type possesses unique characteristics that influence how they respond to electrical stimulation. Research continues to evolve in this area, aiming to optimize the efficiency and effectiveness of these materials, paving the way for innovative applications reminiscent of organic muscle behavior in artificial systems.

Classification of Electroactive Polymers

Electroactive polymers (EAPs) are versatile materials that respond to electrical stimulation by changing shape, volume, or stiffness, making them valuable in the development of artificial muscles. These polymers can be broadly classified into two primary categories: high voltage EAPs and low voltage EAPs. The distinction between these groups is primarily based on the voltage required for activation and the resulting mechanisms of actuation.

High voltage EAPs, also referred to as electrostrictive or dielectric polymers, require substantial electric fields—typically in the range of hundreds to thousands of volts per millimeter—for effective activation. These materials, which include polyvinylidene fluoride (PVDF) and silicone elastomers, capitalize on electrostriction or Maxwell stress to induce mechanical deformation. The significant activation potential enables these polymers to generate large strains, making them suitable for applications requiring considerable force output, such as in robotics and prosthetics.

Conversely, low voltage EAPs operate at much lower voltages, generally under 10 volts. This category encompasses ionic polymer-metal composites (IPMCs) and conducting polymers like polyaniline. The activation mechanism in low voltage EAPs often hinges on ionic movement and electrochemical reactions within the polymer structure. These materials are advantageous in applications where energy efficiency and minimal electrical input are paramount, such as in sensors and soft robotics. The relatively safe operating environment of low voltage EAPs also contributes to their appeal in medical applications, where biocompatibility is essential.

Understanding the classification of EAPs into high voltage and low voltage categories is significant for identifying their appropriate applications in real-world scenarios. As researchers continue to explore the capabilities of these materials, the potential to develop advanced artificial muscles that mimic biological functions becomes increasingly feasible, paving the way for innovations across numerous fields.

High Voltage EAPs: Mechanisms and Characteristics

High voltage electroactive polymers (EAPs) represent an innovative category of materials that respond to an applied electric field. Their unique behavior is primarily governed by electrostatic forces, which induce significant material deformation. This remarkable capability makes high voltage EAPs particularly suitable for applications mimicking artificial muscles.

Among the various types of high voltage EAPs, dielectric elastomers stand out due to their excellent stretchability and energy efficiency. These polymers are typically composed of a low-viscosity elastomer sandwiched between two conductive electrodes. When a voltage is applied across these electrodes, the resultant electric field generates electrostatic attractions that can lead to substantial and reversible mechanical deformation. This deformation capability is enhanced by the inherent elasticity of the elastomer, allowing for rapid responses to changing electric fields.

Another important category of high voltage EAPs is piezoelectric polymers, which operate based on a different mechanism. These materials generate an electric charge in response to mechanical stress, and conversely, they can undergo mechanical deformation when subjected to an electric field. The underlying structure of piezoelectric polymers consists of asymmetric molecular chains that adopt specific orientations under an electric field, enhancing their deformation potential. This characteristic makes piezoelectric polymers particularly effective for applications requiring precise motion control.

One of the key attributes of high voltage EAPs is their operational speed. Both dielectric elastomers and piezoelectric polymers are capable of rapid response times, making them ideal candidates for real-time applications where quick actuation is critical. The combination of their lightweight structures and efficient electrostatic mechanisms positions high voltage EAPs as a front-runner in the search for advanced artificial muscles. Their potential to revolutionize various fields, including robotics and medical devices, marks them as a pivotal focus of research and development in the electroactive polymers domain.

Low Voltage EAPs: Mechanisms and Applications

Low voltage electroactive polymers (EAPs) are a fascinating area of research that offers innovative solutions in the field of artificial muscles. These materials derive their functionality from the movement of ions within their structure, enabling them to exhibit remarkable mechanical properties when subjected to electrical stimulation. The underlying mechanism of low voltage EAPs primarily revolves around ionic conductivity, which is crucial for their performance in various applications. This section delves deep into the ionic mechanisms and the movement of ions, providing a comprehensive understanding of these polymers.

The components of low voltage EAPs often consist of polymer-ion-metal composites. The polymer matrix serves as a flexible substrate, while ions infused within the polymer enable the conversion of electrical energy into mechanical movement. The low voltage operation of these materials is particularly significant as it facilitates energy-efficient actuation, thereby extending their applicability in energy-conscious environments. This low voltage characteristic also minimizes the risk of overheating, making EAPs suitable for sensitive applications, including soft robotics and wearable devices.

Several applications make use of low voltage EAPs, capitalizing on their unique properties. For instance, they are widely used in actuators for prosthetic limbs, where precise control and flexibility are essential. Another promising application lies in the realm of soft robotics, where low voltage EAPs can mimic natural muscle movements, providing enhanced dexterity and responsiveness in robotic systems. Additionally, low voltage electroactive polymers are becoming increasingly relevant in medical devices, such as drug delivery systems that require gentle yet effective actuation, emphasizing their potential to revolutionize various industries.

Breakthrough Applications of EAPs

Electroactive polymers (EAPs) have emerged as a revolutionary material in various fields, particularly in the development of artificial muscles. These materials possess the unique capability to change shape or size when subjected to an electric field, which has opened up numerous innovative applications across different industries.

In the field of soft robotics, EAPs are critical for creating soft actuators that mimic the movement and flexibility of biological muscles. By integrating these polymers into robotic systems, developers can design robots that are not only lighter but also capable of performing tasks that require a softer touch, such as picking up delicate objects. This adaptability enhances the functionality of robots in environments ranging from warehouses to medical settings.

Biomedical applications have also benefited significantly from the use of EAPs. The development of biomedical actuators can lead to advanced prosthetic devices that offer improved movement and responsiveness, closely replicating the natural motion of human limbs. Furthermore, EAP-based devices have the potential to be used in minimally invasive surgeries, where precision and control are paramount.

Flexible electronics is another area where electroactive polymers are making a profound impact. EAPs can be incorporated into wearable technology, allowing devices to respond to user movements and physiological signals in real time. This advancement holds tremendous potential for health monitoring devices and smart textiles that could change the way we interact with technology on a daily basis.

Additionally, EAPs are revolutionizing the concept of smart coatings and energy harvesting solutions. These materials can be used to create surfaces that react to environmental stimuli, generating energy from mechanical movements. This capability is essential in developing sustainable energy solutions, making EAPs a key component in the transition towards greener technologies.

In conclusion, the versatility and responsiveness of electroactive polymers position them as a game-changing element in various applications, particularly in artificial muscles. As research continues to advance, the potential of EAPs will undoubtedly expand even further.

Comparative Advantages of EAPs Over Traditional Technologies

Electroactive polymers (EAPs) present numerous advantages over traditional electromagnetic systems, making them a compelling choice for various applications. One of the most notable characteristics of EAPs is their lightweight nature. Unlike electromagnetic systems, which often rely on heavy components such as motors and gears, EAPs can be engineered into lightweight forms, significantly reducing the overall mass of devices in which they are implemented. This lightweight characteristic is particularly beneficial in mobile applications, where weight savings can lead to improved performance and efficiency.

Another significant advantage is the flexibility of EAPs. These polymers can be easily molded into various shapes and sizes, allowing them to conform to complex geometries that traditional systems may struggle to accommodate. This flexibility opens up new possibilities in design and application, particularly in soft robotics and wearable technologies, where adaptability is paramount. Furthermore, EAPs can provide a degree of elasticity that enhances their functionality, enabling them to act like natural muscles.

Noise levels associated with operation also highlight the superiority of EAPs. Traditional electromagnetic devices often generate significant noise due to moving parts interacting within their mechanisms. In contrast, EAPs operate silently, which is advantageous in applications requiring discretion, such as prosthetics or medical devices. This absence of noise not only contributes to user comfort but also enables the use of these systems in environments where sound levels must be tightly controlled.

Moreover, efficiency is another area where electroactive polymers excel. EAPs tend to consume less energy compared to their electromagnetic counterparts, leading to prolonged operational life and reduced energy costs. This efficiency stems from their ability to directly convert electrical energy to mechanical movement without the intermediary components that typically consume additional power. As industries move toward more sustainable practices, the efficiency of EAPs positions them as a forward-thinking alternative.

Future Prospects and Research Directions

As the field of electroactive polymers (EAPs) continues to evolve, researchers are enthusiastic about the numerous prospects it offers for artificial muscle applications. Current investigations are predominantly focused on enhancing the performance characteristics of these polymers, including their actuation speed, energy efficiency, and lifespan. One of the fundamental challenges that must be addressed is the scalability of production methods. While laboratory-scale synthesis has produced promising results, transitioning to an industrial scale often presents hurdles in maintaining quality and performance consistency. Therefore, future research will likely emphasize developing optimized manufacturing processes that are both economically feasible and environmentally sustainable.

Another critical area of inquiry pertains to improving the mechanical properties of EAPs. As artificial muscles, these materials must replicate the functionality of biological tissues effectively. Researchers are exploring various formulations and composite structures that could potentially enhance their tensile strength and flexibility, while also maintaining lightweight characteristics. Innovations in nanotechnology may offer pathways for integrating advanced materials that can achieve these desired features.

Furthermore, the scope of applications for electroactive polymers is vast and varied. Beyond traditional uses in soft robotics and prosthetics, speculative advancements could usher in next-generation technologies, such as self-healing materials and smart textiles. These innovations could redefine how EAPs are integrated into our daily lives, ranging from responsive wearable technology that monitors health to advanced mechanisms in biomedical devices that mimic natural muscle movement. The interdisciplinary nature of ongoing research, encompassing fields such as materials science, engineering, and biology, will undoubtedly play a pivotal role in realizing these potential applications. As such, the future of electroactive polymers is not only promising but also filled with limitless possibilities for innovation and application across various sectors.

Conclusion

Electroactive polymers (EAPs) represent a groundbreaking advancement in material science, showcasing their potential as artificial muscles. These versatile materials convert electrical energy into mechanical movement, mimicking the functionality of natural muscle tissue. As explored throughout this blog post, EAPs possess unique properties that distinguish them from traditional actuators, including lightweight construction, adaptability, and energy efficiency. Their capacity for stretch and contraction opens up a myriad of applications in robotics, prosthetics, and various fields within biomedical engineering.

The significance of electroactive polymers extends beyond their mechanical capabilities. By integrating this technology into everyday devices, EAPs can enhance functionality and performance, creating smarter and more responsive products. For instance, their potential impact on wearable technology signifies a shift toward more interactive and intuitively designed devices, potentially revolutionizing how we interact with technology in our daily lives.

Moreover, the ongoing research and development in the field of EAPs continue to uncover new opportunities for innovation. As scientists and engineers refine the materials and techniques related to electroactive polymers, it is likely that we will see improvements in durability, responsiveness, and environmental sustainability. The evolution of these materials will not only lead to groundbreaking innovations but could also address significant challenges in energy consumption and material efficiency across various industries.

In light of these developments, it is essential for industry professionals, researchers, and technology enthusiasts to remain informed about advancements in electroactive polymers. The future holds promising implications, as EAPs are poised to significantly influence multiple sectors, from healthcare to consumer electronics. Embracing the potential of this technology will undoubtedly lead to innovative solutions, shaping the landscape of artificial muscles and beyond.

You might also like:

- Excitement Builds for the North London Derby: Arsenal vs. Tottenham

- Experience the Magic of Dilworth Park on December 10, 2025

- Real Madrid Dominates Valencia: A 4-0 Triumph to Maintain League Supremacy

- Market Summary: U.S. Stocks Edged Down Amid AI Play Rotation

- Economic and Fiscal Challenges Facing the French Economy