Introduction to 3D Printing and Its Impact on Manufacturing

3D printing, also known as additive manufacturing, has emerged as a transformative technology across various industries, revolutionizing traditional production methods. This innovative process involves creating three-dimensional objects by layering materials based on digital models. The technology encompasses a range of techniques, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS), each offering unique benefits tailored to different applications.

One of the most significant advantages of 3D printing is its material efficiency. Unlike conventional subtractive manufacturing processes that cut away material to create parts, 3D printing adds material only where needed. This reduction in waste is particularly valuable in industries that rely on expensive materials, allowing for more sustainable production practices. Businesses can leverage this efficiency to minimize costs, thereby enhancing their competitive edge.

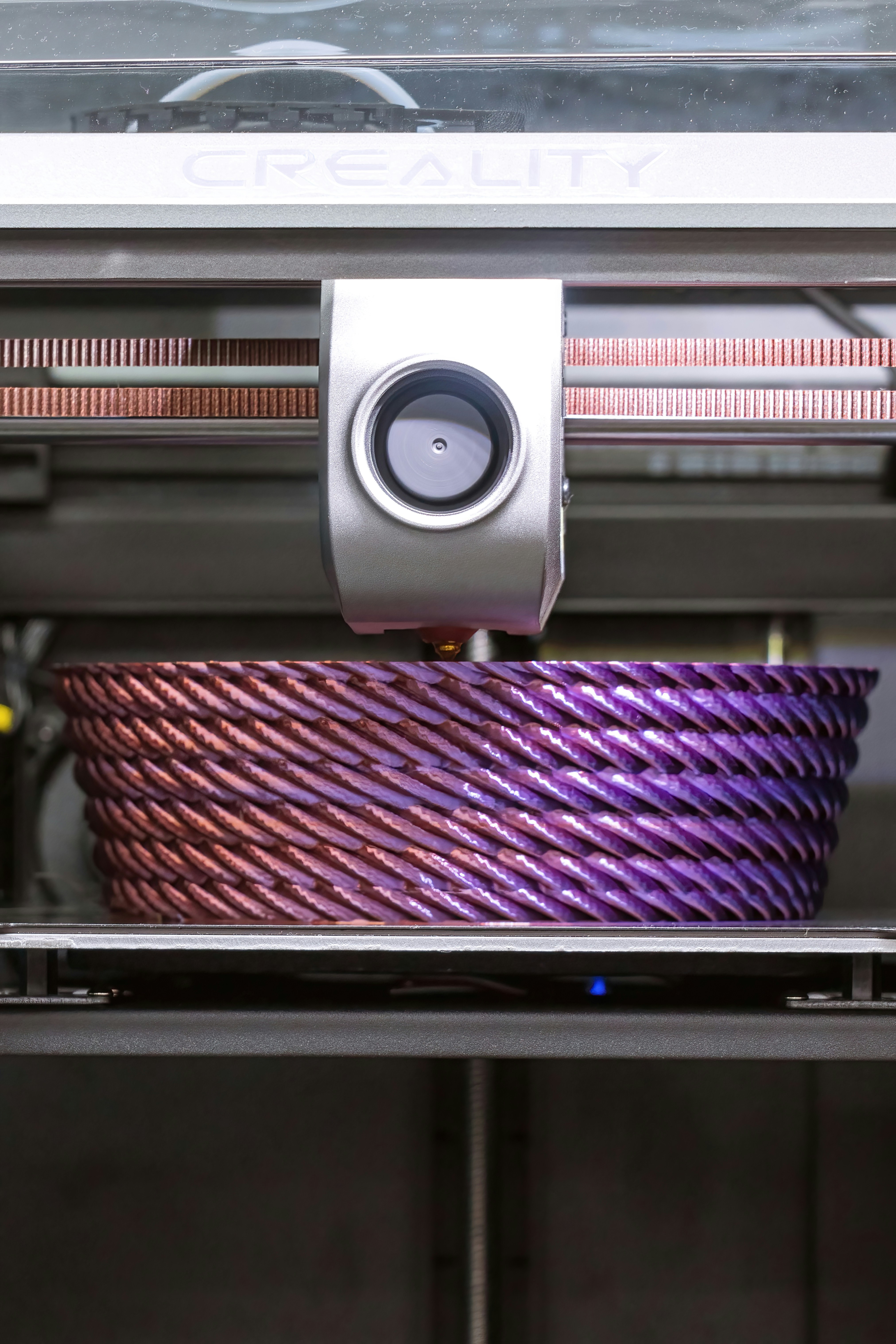

The impact of 3D printing on manufacturing extends beyond material savings. This technology fosters the creation of intricate designs that would be challenging or impossible using traditional methods. Complex geometries can be produced without the constraints typically associated with conventional tooling, enabling designers and engineers to innovate freely. This capability not only enhances product performance but also opens new avenues for creativity in design.

Furthermore, 3D printing supports rapid prototyping, allowing companies to quickly test and iterate their designs. This accelerates the development timeline, enabling faster time-to-market for new products. As industries adopt 3D printing technologies, the reduced lead times and increased customization capabilities become vital components in meeting consumer demands and staying relevant in an ever-evolving market.

Overall, the integration of 3D printing into manufacturing processes signifies a major shift in how products are designed and produced, paving the way for advanced, efficient, and sustainable practices.

Apple’s Sustainable Approach: The Case of the Titanium Watch

In recent years, Apple has made concerted efforts to integrate sustainability into its production processes, especially reflected in the use of titanium for its Apple Watch Ultra 3 and Series 11. Titanium is recognized for its excellent strength-to-weight ratio, durability, and resistance to corrosion, making it a highly desirable material for high-end products. Its lightness allows for comfort in wearable technology, while its robustness ensures longevity, thus enhancing the overall user experience.

Apple’s decision to utilize titanium aligns with its broader sustainability objectives, which aim to minimize the environmental impact of production. By adopting innovative manufacturing techniques, Apple has announced a significant achievement: saving 400 tons of titanium while producing the Apple Watch. This is not merely a reduction in material usage; it embodies a paradigm shift in how consumer electronics can be manufactured sustainably. Through advanced 3D printing technologies and precise engineering, Apple has optimized the extraction and processing of this metal, ultimately leading to less waste and more efficient use of resources.

This commitment to sustainability is a core element of Apple’s production philosophy, which emphasizes responsible sourcing and eco-friendly materials. The company has taken tangible steps towards a circular economy, wherein products can be recycled and reused even after their life cycle. The choice of titanium not only underlines their innovative approach but also signals to consumers a commitment to environmental stewardship. As the demand for sustainable products grows, Apple’s actions demonstrate that it is possible to produce high-quality technology while being conscientious about ecological impacts.

The Technology Behind 3D Printing Titanium Cases

3D printing, also known as additive manufacturing, is a transformative technology that has significantly altered the landscape of production, particularly in industries that require materials such as titanium. This process involves creating three-dimensional objects layer by layer, which is distinctly different from traditional subtractive manufacturing methods that often waste substantial amounts of material. For Apple, utilizing 3D printing to manufacture titanium cases has yielded both economic and environmental benefits, evidenced by their remarkable saving of 400 tons of titanium.

When printing titanium, several methods can be employed, but the predominant technique utilized by Apple is Selective Laser Melting (SLM). SLM uses a high-powered laser to fuse fine layers of titanium powder into a solid structure. This method not only enables precision and accuracy in design but also minimizes waste, as only the necessary material is utilized in the production process. SLM’s ability to produce complex geometries allows Apple to create intricate patterns and lightweight structures that would be challenging or even impossible to achieve through conventional manufacturing methods.

However, the journey of 3D printing with titanium is not without its challenges. One major issue is the control of the thermal properties of the material during the printing process. Inadequate thermal management can lead to defects within the final product, undermining its structural integrity. Apple has developed advanced strategies to address this concern, including optimized cooling systems and sophisticated software algorithms that monitor and adjust laser parameters in real-time.

Furthermore, post-processing is a vital stage in achieving a high-quality finish on 3D printed titanium cases. This may involve processes such as surface polishing and heat treatment, which enhance the material’s durability and aesthetic appeal. By harnessing 3D printing technology, Apple not only reduces waste and improves efficiency but also achieves a level of customization and design flexibility that positions them at the forefront of innovation in manufacturing.

Looking Ahead: The Future of 3D Printing in Eco-Friendly Manufacturing

The success of Apple in utilizing 3D printing to save substantial amounts of titanium serves as a significant case study for the broader manufacturing industry. As companies increasingly prioritize sustainability, the implications of adopting 3D printing technology extend beyond just material savings. The ability to produce components with reduced waste not only addresses environmental concerns but also aligns with a growing consumer demand for eco-friendly practices.

In the coming years, we can expect to see advancements in 3D printing technology that will further enhance its efficiency and environmental benefits. Innovations such as bioprinting and the use of recycled materials are likely to gain traction, allowing manufacturers to create products that are not only efficient in design but also sustainable. For instance, integrating biodegradable materials into 3D printing processes may drastically reduce the carbon footprint associated with traditional manufacturing methods.

The potential for widespread adoption of 3D printing is noteworthy. As more companies, following Apple’s example, begin to incorporate this technology, industries ranging from aerospace to fashion may experience transformations in their production frameworks. The shift towards eco-friendly manufacturing practices can lead to a significant decrease in the overall consumption of raw materials, prompting ecosystems to recover and thrive.

Moreover, as regulatory policies become increasingly stringent regarding waste and carbon emissions, 3D printing can provide companies with the flexibility to adapt to these changes. By leveraging data-driven designs and optimizing production methods, businesses can ultimately achieve more sustainable outcomes.

In conclusion, the future of 3D printing in eco-friendly manufacturing appears promising. As industries scrutinize their production methods, the integration of 3D printing could herald a new era focused on sustainability, waste reduction, and innovative practices, fostering significant environmental benefits globally.